Rail Failure | Types of Rail Failure

- Amrut Gardalwar

- Aug 5, 2020

- 2 min read

Rail failure

Sometimes the rails fail suddenly without any notice. The important factors which influence the number of rail failures are as follows.

1. Axle load of locomotive

2. Constant reversal of stresses

3. Defects of manufacture

4. Design of rail joints

5. Fatigue caused by shearing stress

6. Frequency of rail renewal

7. Maintenance of rails joints

8. Rail length

9. Rail quality

10. Rail section

11. Rail welding

12. Speed of trains

Types of rail failure

1. Crushed head

The head of the rail gets crushed and the metal flows on the head of the rail. The crushed heads are due to defect of the manufacture, flat spots on wheels, slipping of wheels and weak support at the rail end. The skidding of wheels develops the flat spots on wheel and loose fish-bolts result in the weak end support.

2. Transverse fissure

This is developed in the form of fissure or a hole in the head of the rail. It is in the form of a cross –wire crack which starts from a point inside the head and spread gradually like the shape of contours. The broken surface exhibits a smooth oval or round bright spot. The transverse fissure is due to defect of manufacture or due to overstraining of metal in service.

3. Split head

In this type of failure, the head of rail is split up into two parts. If the surface of the crack appears smooth and dark, when opened the defective rail is known as the piped rail and this is due to cavity formed during manufacture or due to shrinkage of the metal being not closely welded together.

4. Horizontal fissure

In this type of failure, a fissure is developed in the section of the rail and it gradually goes on increasing. This supposed to be the outcome of worn fish-plates or insufficient ballast packing under the joint sleeper.

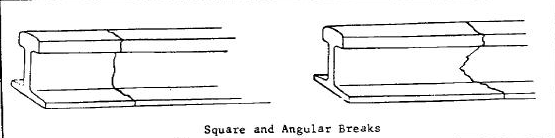

5. Square or angular breaks

In this type of failure, the rail breaks either in a vertical plane or in inclined plane.

_edited.jpg)

Comments